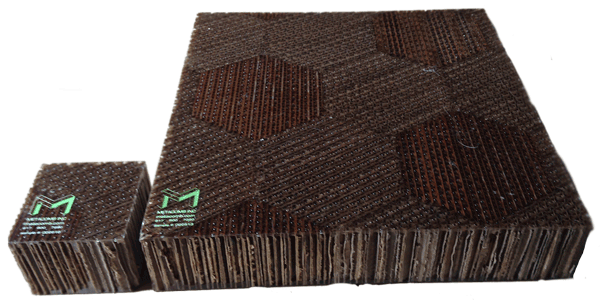

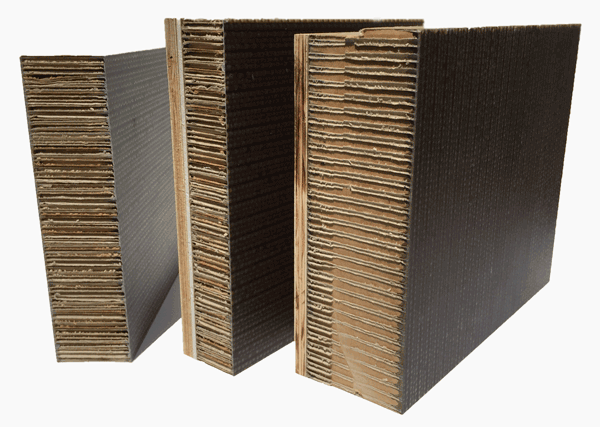

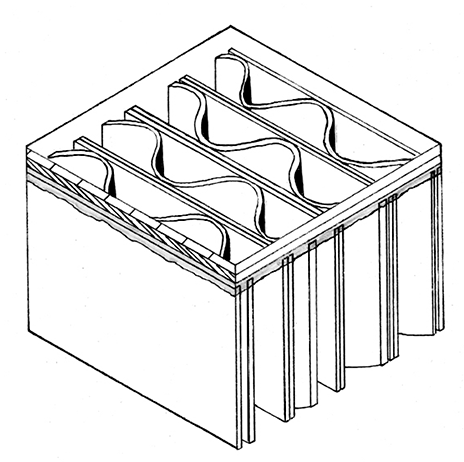

MetaComb, Inc. (MCI) is a developer and manufacturer of composite honeycomb panels that are made from upcycled corrugated cardboard that is replacing wood-based materials and products used in building and in shipping.

The company, a Delaware C corporation founded in 2010 by Vsevolod Tsodokov, the company’s CEO and original inventor of MetaComb™ material. The company has been demonstrating a significant market demand for its product with revenue-driving demonstration projects, and ongoing market driven case-studies.

Sample request form